A game changing inspection device

Truly remote pipeline inspection technology. The result of years of research into stress magnetization.

Leading the way forward

In partnership with the University of Leeds, we've engineered the science of stress-magnetization to create a remote pipeline inspection tool which is used by integrity engineers worldwide on both piggable and non-piggable lines. This groundbreaking technology is called Stress Concentration Tomography, commonly referred to as SCT™.

Comprehensive inspection

The only inspection technique in the world that can map the lateral position and depth of cover of the pipeline while providing comprehensive defect detection.

Innovative technology

Using magnetic signatures to detect wall defects, weld defects, corrosion, SCC, physical features, lateral position and depth of cover.

Comprehensive defect detection

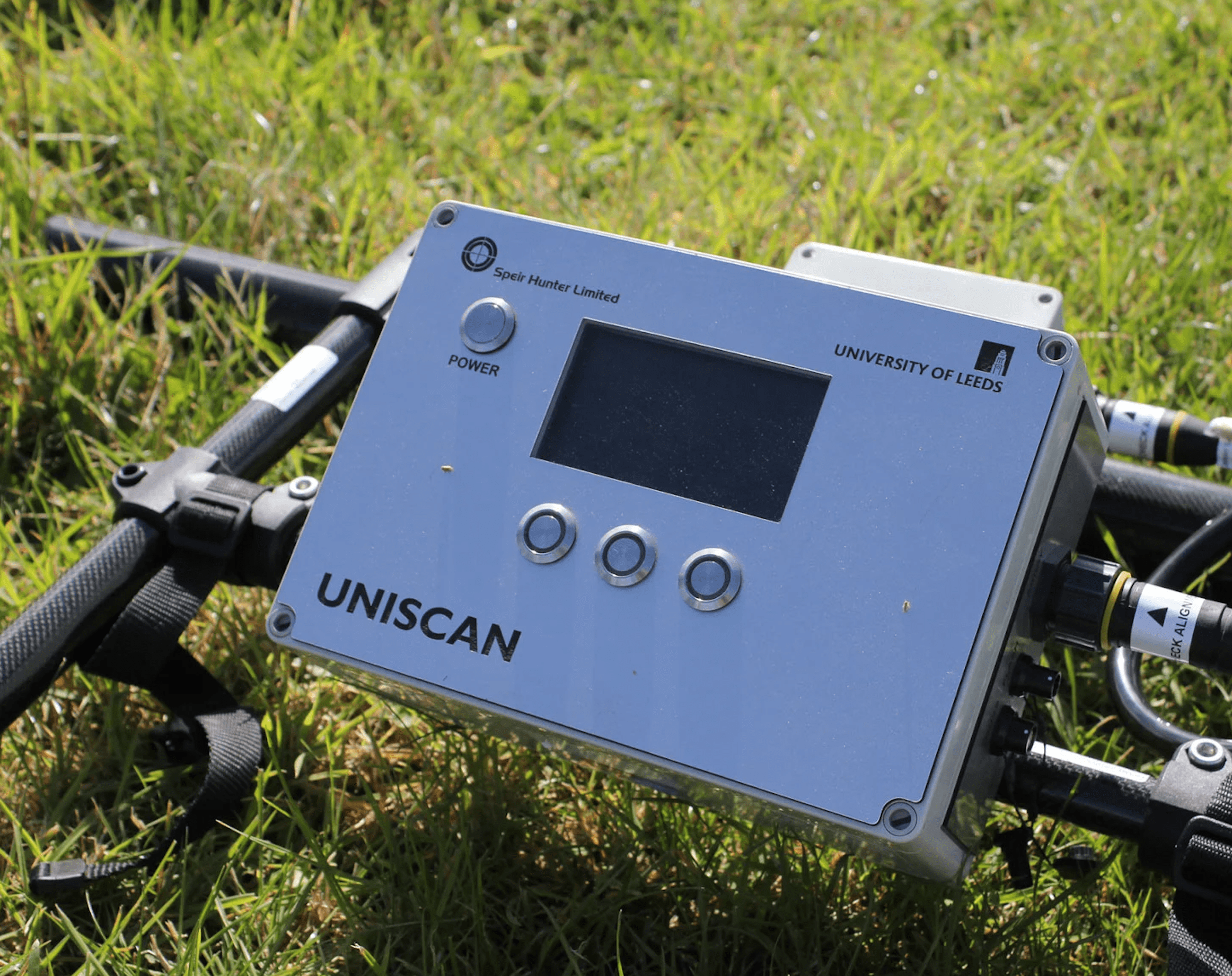

A cost-saving addition to existing methods, weighing less than 8kg and requiring only a 2-man team to operate in the field, UNISCAN™is rapidly mobilized and can be deployed in many different environmental conditions.

Introducing UNISCAN

is the hardware used to collect raw data for analysis. It carries an array of magnetometers that collect the pipeline’s magnetic field in multiple dimensions and an onboard data logger that provides an LED display unit for the field operator to use as he walks along the axis of the pipe.

Complement ILI

and

ECDA with SCT

Most pipeline operators have experienced unexpected additional excavation costs when repairing pipes following ILI reports especially when positioning is based on girth welds. They have also experienced excavations following DCVG reports of damaged coatings only to find no corrosion has initiated in the metal.